CNC Glass Cutting routers are controlled completely by a computer, coordinates are uploaded into the machine’s controller from a CAD program. Bespoke glass cutting with limitless possibilities in shape and glass designs. This ensures there is no possibility of human error.

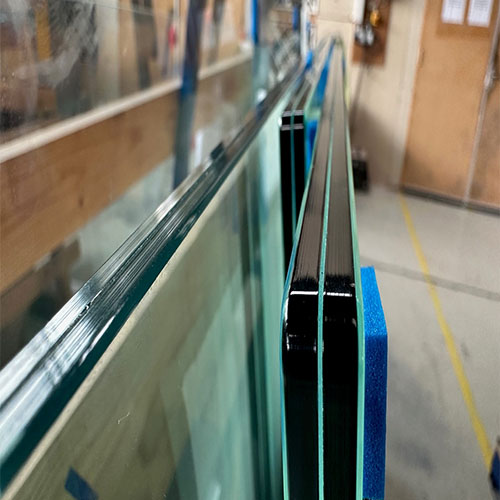

We can process glass from 4mm to 19mm thick with a maximum sheet size of 1600mm x 3000

Splashbacks with socket cutouts are no problem, no matter how complex the template might be.

Onsite templating is available using a ®Prodim Pro -Liner Our equipment digitizes templates to make sure they are 100% correct.

If you have a DXF file we can import that directly to our CNC machine.

CNC machines are capable of producing parts and components with a high degree of precision and accuracy, ensuring consistency in the final product.

CNC machines can operate continuously without the need for breaks, reducing the downtime and increasing the overall efficiency of the manufacturing process.

CNC machines can be programmed to perform quality checks during the manufacturing process, ensuring that the final product meets the required specifications.

CNC machines can produce identical parts and components consistently, ensuring that the final product is of the same quality every time.

CNC machines can be used for both small-scale and large-scale production, making them a suitable option for manufacturers of different sizes.

Digital scanning of templates so the reproduction is perfect. DXF can be imported from AUTOCAD files so there is no room human error.